Image quality and cost performance that

you've been looking for!

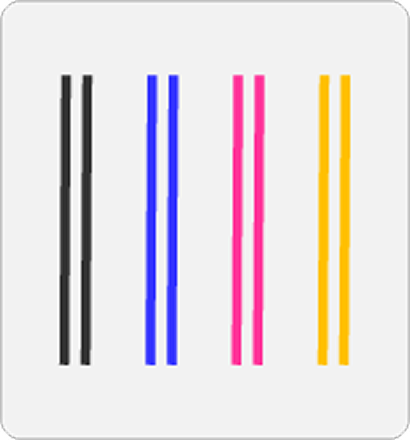

New print head design "AccuFine HD Pro"

Equipped with a high-density "AccuFine HD Pro" printhead, for high-speed, high-quality printing.

Nozzle rows:8

Nozzle count:3200

High density

nozzles

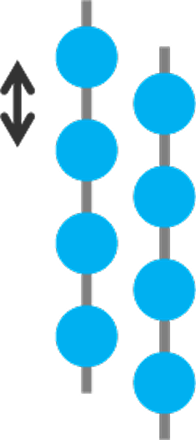

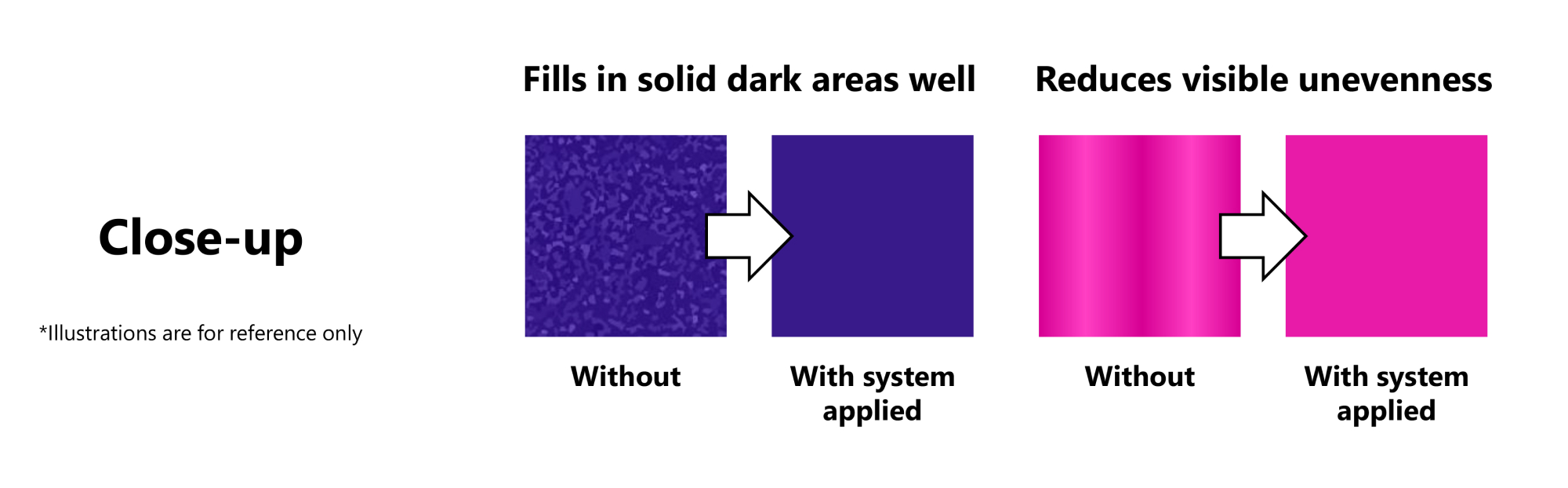

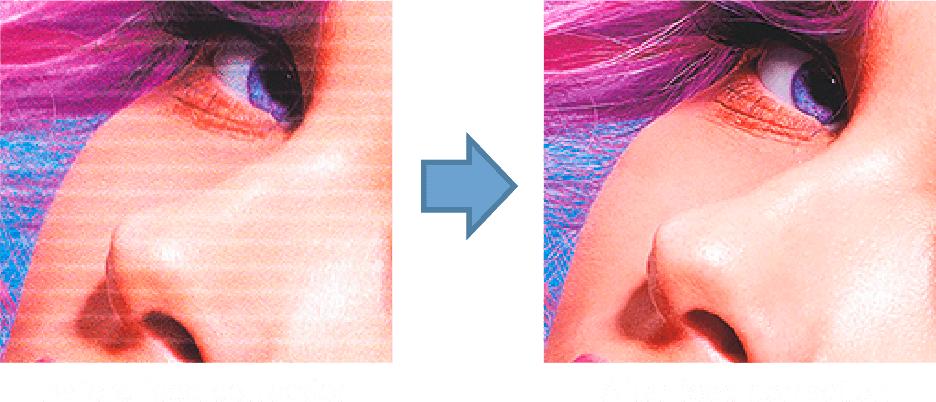

New printing control system that realizes high image quality

"i-Screen EX System"

By controlling the screen, you can improve the unevenness of solid dark areas and reduce unevenness.

When using a Mac/Linux RIP, a separate PC running Windows 11 (Intel CPU) is required to operate this system.

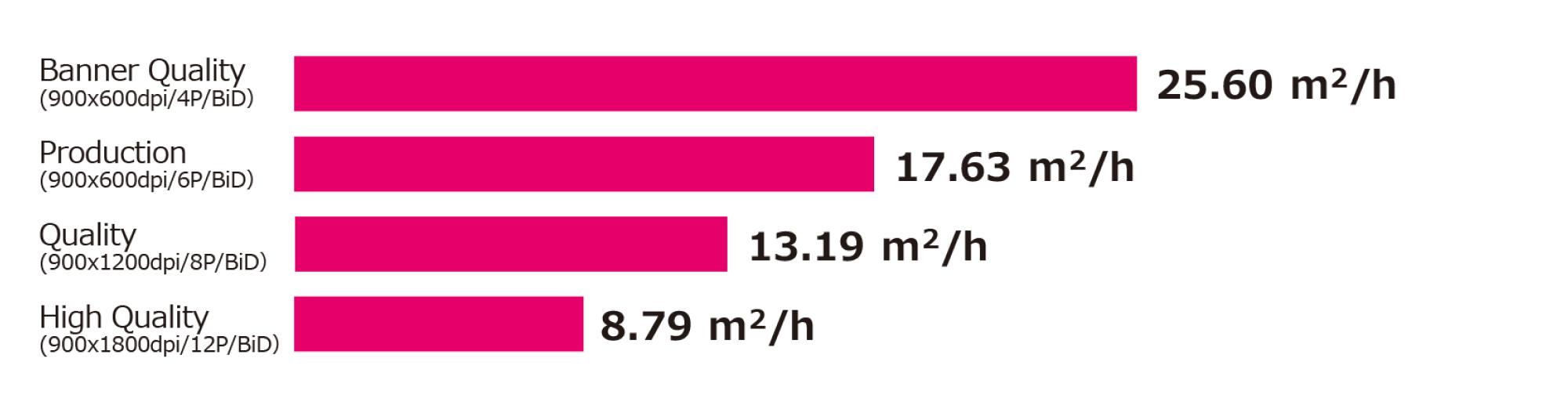

Print speed

It achieves a productivity of 17.63 m2/h in practical printing mode.

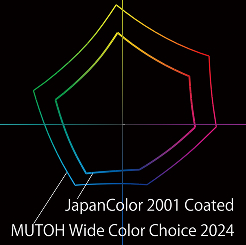

Original input profile

"MUTOH Wide Color Choice"

Introducing “MUTOH Wide Color Choice”, an input profile that maximizes color reproduction of inkjet printers! "MUTOH Wide Color Choice" focuses on dark color areas that were previously difficult to reproduce, expanding the color range. It maximizes the performance of MUTOH inks, enabling printing with even better color reproduction than before.

MUTOH's unique technologies for automation and efficiency

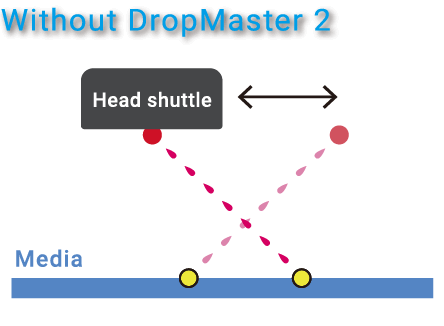

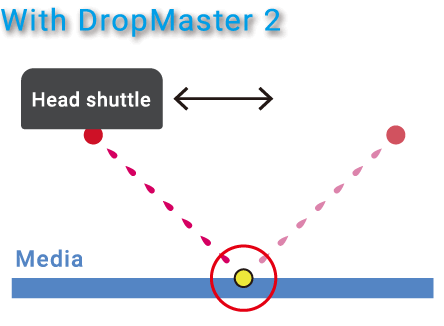

Automatic Bi-D adjustment

“DropMaster 2”

Built-in sensor on the carriage automatically calibrates bi-directional alignments, and saves time and reduces validation in adjustment among different operators.

Automatic media feed adjustment

“FEED MASTER”

By printing a print pattern and reading it with a sensor, paper feed correction can be automated. This reduces the time and effort required for adjustment and media loss.

Nozzle selection Function

"Nozzle Area Select"

Nozzle area select temporarily prints using selected areas of active nozzles when clogged nozzles fail to recover. This is a reliable function that ensures seamless operation.

Media roll balance management

“Media Tracker”

Media tracker manages the remaining media by printing barcodes before removing a roll in use. It will read the barcode when reloading that roll. Streamlines management of remaining capacity for multiple media.

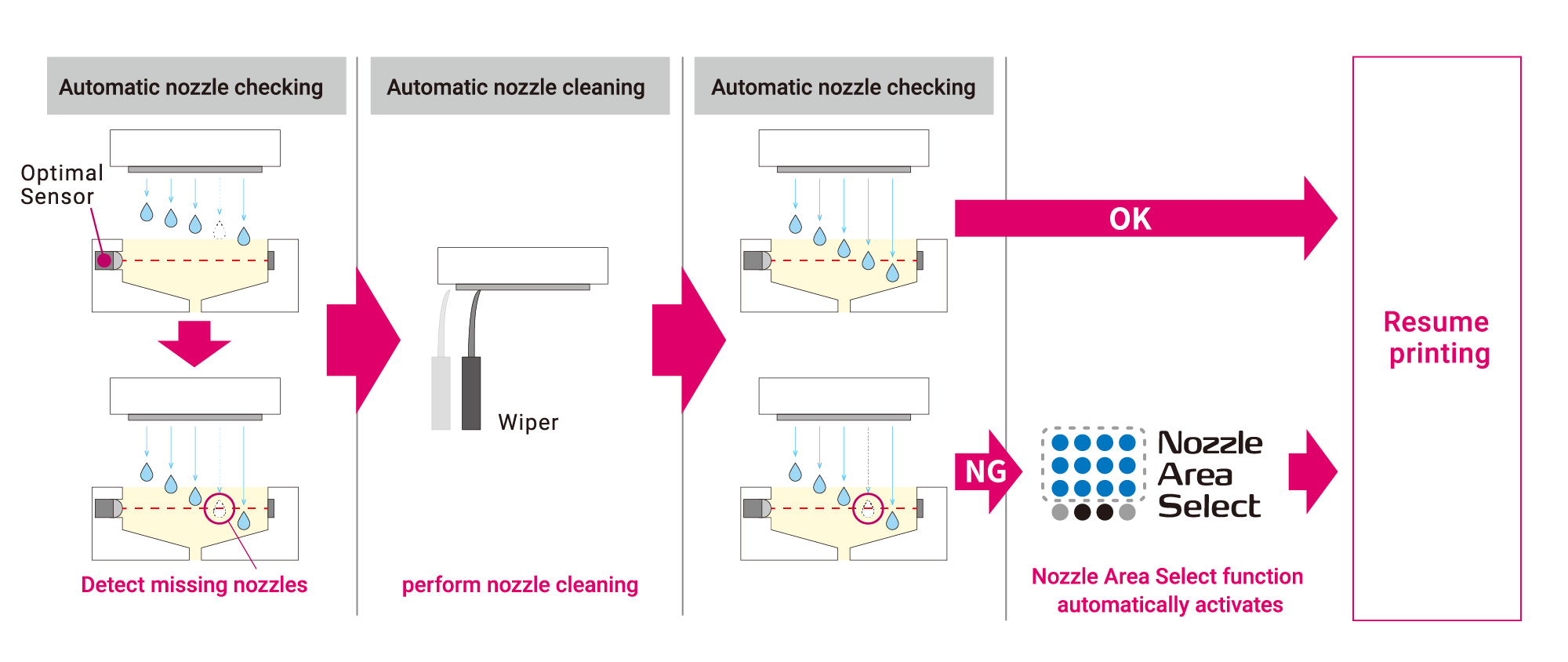

Automatic nozzle checking unit (optional)

It is available to add a module to the print head that can optically monitor the ink jetting. Automatically detects missing nozzles and performs nozzle cleaning. If nozzles are not recovered, the Nozzle Area Select automatically activates to continue printing.

*This function does not guarantee for the perfect accuracy of detection.

High media handling and transport

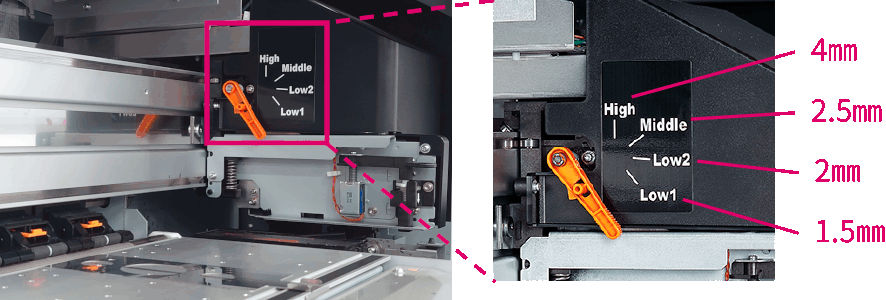

4 step PG setting

PG setting enhanced with 4 steps allows the operators to select the optimal print head height for the media being used. It reduces the risk of print head contact and maintain stable print quality.

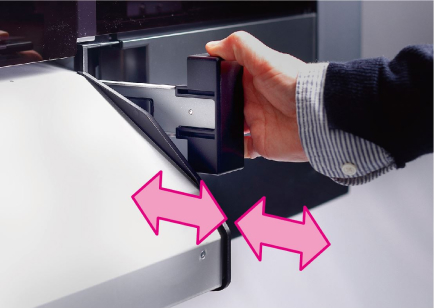

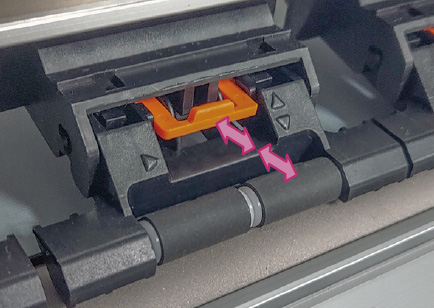

Multi-stage pressurizing mechanism

Media feeding power is affected by pressure and paper thickness. This pressure mode can be set to four levels: high, middle, low and partial pressure by adjusting the position of the media set lever and the pressure arms, which expands media feed capability. Furthermore, media cockling can be minimized by canceling multiple pressure rollers individually.

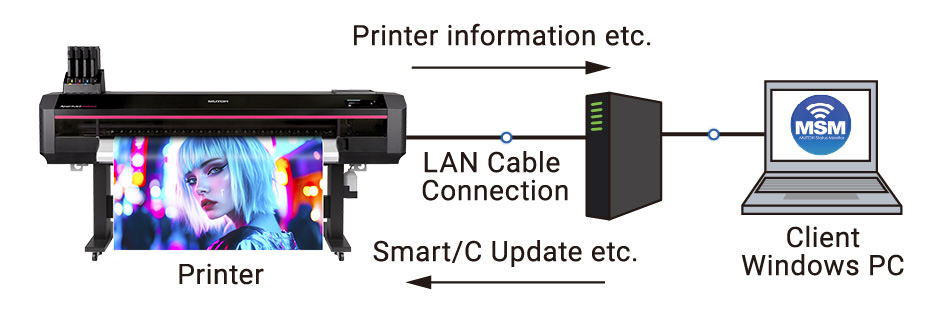

MUTOH Status Monitor(MSM)

MUTOH Status Monitor is software that enables the checking of the printer operation status from a computer in real time.

The following information can be confirmed for your MUTOH printer.

- Detailed information

- Status information

- Heater information

- Print head temperature/cartridge information

- S/C card information

- Print information and print history (job information, print time, ink consumption, cost, etc.)

Print history can be exported as a CSV file.